Learn more about Armada Saw Blades

MATERIALS

If you are looking for a size blade not listed, please contact our sales team directly for an estimate at 763.786.9652.- All the saw bodies are manufactured using cold-rolled steel strips quality 75 Cr1 (Material No. 1.2003) bright hardened and annealed to 42-46 HRC.

- Laser-cut saw bodies and expansion slots, using the latest technology. Some saw blade types are provided with copper plugs in order to reduce the turbulent noise.

- Extra-large European carbide tips. Depending on the specific sawing application the selected submicron grade carbide tips are used for high resistance and also micro-grain structure to obtain the best edge.

- The carbide tips are braced automatically using Tri-Metal shim providing high tensile strength and impact resistance.

- H7 ISO metric tolerance system bore. This ensures the maximum performance of the saw blades by giving precise tensioning, run out, and clearance angles.

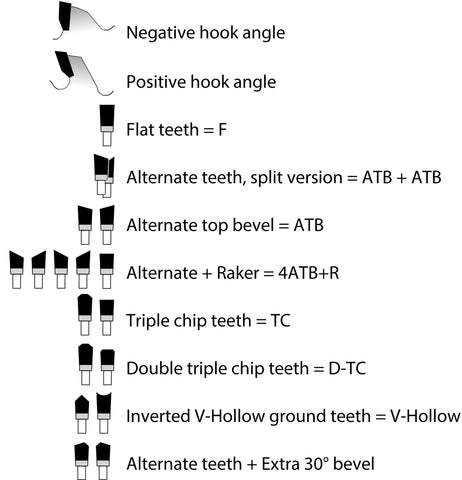

HOOK ANGLES AND TOOTH SHAPES

|

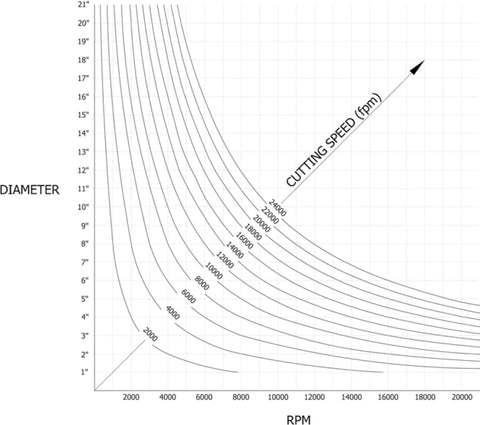

CUTTING SPEED DETERMINATION

|

Cutting speed calculated in feet per minute (fpm) derived from the saw blade diameter and the RPM

| MATERIALS | SUGGESTED FPM |

| Softwood | 14000 - 20000 |

| Hardwood | 14000 - 18000 |

| Laminated Board | 12000 - 16000 |

| Chipboard | 12000 - 20000 |

| Aluminum | 6000 - 12000 |